DroneQ Robotics is a data-centric organization that has been using various (unmanned) technologies for several years to collect that data as efficiently as possible and of the highest possible quality. DroneQ Robotics is not an ROV or drone company that performs inspections with the resources available, but an organization that looks very explicitly at what is needed to collect the highest possible quality data as efficiently as possible and provide the necessary technology and processes.

Our own experience has shown that 95% of the inspection data is of limited value: where no deviations (anomaly) are detected, and only validated that there are no deviations. The remaining 5% is the interesting data: deviations from the normal state such as damage, corrosion or the presence of foreign objects or objects. This fact lies at the basis of the optimized Marine Asset Integrity Management inspection methodology that DroneQ Robotics has developed.

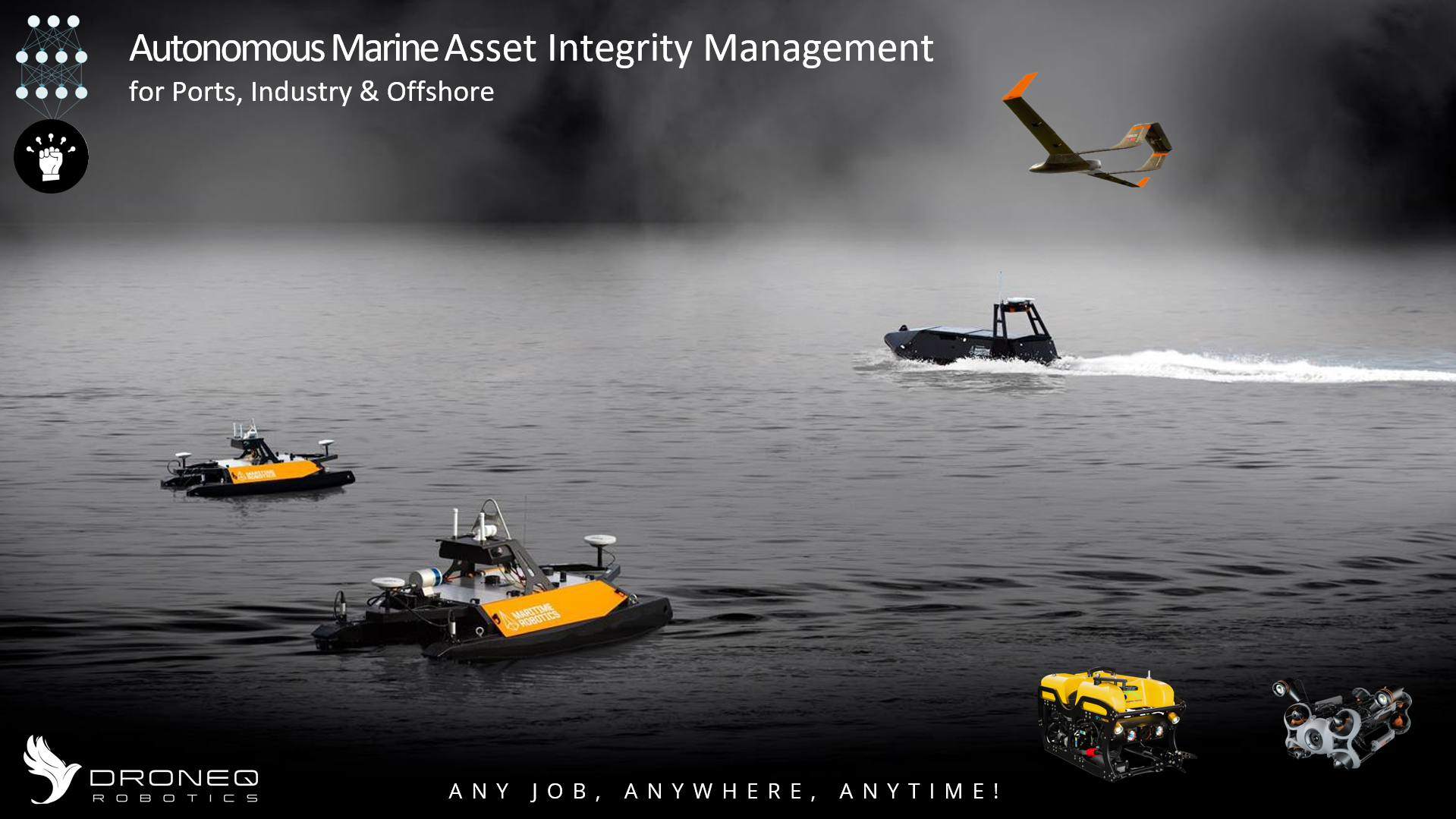

In order to be maximally efficient for inspecting industry, ports and Offshore, DroneQ Robotics uses various technologies to support a holistic inspection methodology to carry out the different phases and process steps of the inspection efficiently and effectively: data collection, deviation validation, data enrichment and data processing and reporting.

Safety is paramount and it is important that the solution does not cause any danger or hindrance to the port and offshore activities. The latest technology in the field of detect & avoid are used: LIDAR, 360 degree cameras, AIS and radar supported by AI and a neural network. Redundant communication systems and the right processes are also used for a safe integration between manned and unmanned traffic.

Data collection

DroneQ Robotics deploys highly advanced ASVs (Autonomous Surface Vessels) with ultra high resolution 3D/4D multibeam sonar to survey and inspect the underwater part of ports with survey accuracy in a short time.

Findings such as damage, soil accumulations, wear and tear (scouring) and foreign objects or objects (debris) are mapped in a very detailed, efficient and climate-neutral way. The ASV is also equipped with LIDAR (Laser Imaging Detection And Ranging) to inspect the surface part with high precision, such as quays, sheet piling, dikes, and the objects on them such as cranes, buildings, et cetera.

Inspection objects include port infrastructure, tanks of ships and industry, offshore installations such as production platforms and offshore wind turbines. The platform is also suitable for ecological survey Inshore and Offshore.

Deviation validation

The deviations are then validated with a specially prepared Fast Response ROV (underwater robot): highly transportable and equipped with the latest technology for maintaining position on fast-flowing water by means of DVL (Doppler Velocity Logging), and underwater navigation and trajectory plotting by means of USBL (Ultra-short Baseline), an acoustic underwater positioning system.

For inspections, inspection ROVs are used, which are equipped with metal wall thickness measurement probes, cathodic protection (CP) anode measurement probes, an in-house developed device to test the integrity of underwater cement of frame walls and wood from, for example, inhibition work.

If a larger area or object needs to be inspected, drones are also used for high-resolution inspection and point clouds/photogrammetry and 3D mapping.

Data enrichment

DroneQ Robotics already carries out various projects for autonomous object recognition, such as underwater fouling, corrosion and damage with the help of Artificial Intelligence.

Data Processing

All survey and inspection data collected by the various technologies such as ASVs, ROVs, drones, iPhones, et cetera, will be stored and processed on a technology-agnostic cloud-based Asset Integrity Management system. Data Science is a program of DroneQ Robotics and will be used to analyze the data for predetermined deviations (anomalies) and be automatically annotated.

The results are presented in a uniform manner and possibilities such as trend analyses, reporting and links with external systems such as Asset Management Systems are possible.